3D Scanning to Enable Sub-sea Connections

Fast, Accurate Surveying of Underwater Tunnels in Norway

一家挪威土木工程建筑公司正在使用3D扫描来调查两条关键的水下道路隧道。MESTA选择了Trimble SX12扫描总站,以从总站点测量的高精度中受益,并结合3D扫描的速度和精度。

挪威运输部目前正在促进一项诺克(Nok)2.11亿(约2100万欧元)的项目,以翻新Maursund和KågenTunnels - 两条关键的水下道路隧道,这些隧道将诺德里萨(Nordreisa)的诺德里萨(Nordreisa)与凯吉维(Skjervøy)连接起来。

Both tunnels were built in 1991 and are about 2km long. The Maursund Tunnel runs under the Maursundet Strait to connect the mainland part of the municipality of Nordreisa with the island of Kågen in Skjervøy. It reaches a depth of 92.5m (303ft) below sea level and some sections of the tunnel have a 10% gradient. The Kågen Tunnel passes through the Kågen mountain, which is vulnerable to avalanches and landslides. The renovation project includes extensive upgrades to each tunnel, including the widening of the carriageways as well as installing new LED lighting, CO/NO2gas meters, new water and frost protection and new drainage systems, plus paving new road surfaces.

Mesta AS, a civil engineering construction company based in Lysaker, Norway, is tasked with managing all the construction crews’ survey needs. Sylvia De Vuyst, a professional surveyor at Mesta AS, is responsible for handling the project surveying scope, which includes managing the geodetic control network.

Ideal for underground surveys

De Vuyst realized immediately after the first site visit that traditional survey tools such as conventional total stations would not work due to several challenges, including low light visibility in a GNSS-restricted environment and the need to measure long linear underground distances with high accuracy. Moreover, the Maursund Tunnel needed to remain open for traffic 24/7, which called for considerable flexibility from the entire team of surveyors and contractors alike. De Vuyst therefore decided that instead of using a traditional total station for setting geodetic control, measuring material volumes, marking ventilation bolts and more, she needed something else out of her technology toolbox. She opted to use a Trimble SX12 scanning total station, which combines the high accuracy of total station point measurements with the speed and precision of 3D scanning. According to De Vuyst, the total station and scanner combination is particularly well-suited for underground survey projects like tunnels from start to finish.

Reliable reference points

At any given time, there are multiple teams of upwards of 50 people working in the Maursund Tunnel. De Vuyst is responsible for providing consistent and reliable reference points and as-built versus design-intent comparisons. Using the instrument’s robotic total station, she established ground control fixed prisms at 80m intervals along the tunnel walls, which allowed for a control network accuracy of 0.005m. She then used the scanning total station to establish and measure metre lines (the horizontal lines that are sprayed every 10m) to indicate the 1m mark above the road surface. “The existing road has steep gradients descending down around 80m and it curves, so it isn’t a reliable reference,” says De Vuyst. “We know the elevation and design of the new road so I can use that theoretical data and the SX12 to measure and set out the metre line. That data gives crews a physical position in the tunnel and it provides a marker to follow for determining their own work, such as laying cables or installing reinforcing materials on the walls.”

Calculating earthwork volumes

One of De Vuyst’s primary jobs during the blasting and digging operations inside the tunnel is to calculate volumes to ensure that sufficient material is removed to expand the road and hard shoulders in line with the plans (i.e. to create a 6m-wide carriageway with a 1.2m hard shoulder on each side and a clear height of 4.6m). To support the effort, she developed a 3D tunnel design in Trimble Business Center (TBC) that she imported into Trimble Access (TA) Tunnels software and saved as a master file on a Trimble TSC7 controller. Based on the tunnel shape model, she combined survey controls with the scanned model to create a tunnel profile drawing that can be used to calculate and verify earthwork volumes.

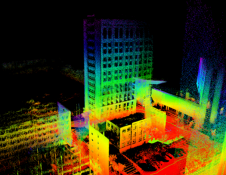

一旦爆破或挖出部分,de Vuyst捕获了全盘扫描,从而形成了一个区域的地理参与点云,通常为60m。她将数据集成到TBC和该软件的专业隧道模块分类工具中,以自动清洁和处理数据以创建隧道形状 - 每次扫描需要三分钟的过程。现在,她可以随时通过定位SX12,测量任何点并立即确定与控制器图形界面上可见的驾驶箱周长相关的任何突破。de Vuyst解释说:“如果没有Trimble Business Center中的自动分类工具,我必须手动选择每一点噪声并删除它。该功能以及自动进行扫描的自动扫描节省了我的时间处理时间。”

Once the comparison is complete, the operators use the updated drawing prints in their cabs to guide digging and blasting. De Vuyst has also been creating 3D ‘profile prints’ – drawing files that provide the tunnel shape, tunnel bottom, driving box and a numbered position marker for tunnel orientation to help the entire team monitor the progress. In addition to checking and calculating volumes, De Vuyst has had to set and check around 170 prisms and reinforcement, lighting and signage bolts. “The clarity, precision and range of the SX12’s green laser makes the task much easier,” she comments. “Even at 100 metres away, points are crystal clear.”

Easier data management

的一个主要难点在今天的技术-enabled operations is managing large volumes of data, particularly the billions of data points produced by 3D laser scanners, for construction verification and reporting purposes. Sifting through the unwanted data such as machinery, duct work and operators and aligning the scan data to the tunnel design is often tedious and costly. The SX12’s workflow is designed to simplify much of the data processing. The generated scan data is automatically georeferenced to the survey control backsight or resection setup measurements, eliminating the need for time-intensive point cloud registration and processing. Meanwhile, tools in TBC Tunneling automatically remove unwanted data, thus saving technicians considerable time in the office. Additionally, the solution enables surveyors to automatically generate detailed as-built reports verifying the tunnel’s as-built position and over/underbreak values. In shotcrete and excavation quality control, the scanning data can be used to generate customizable heat map reports to verify thickness, undulation and conformity to the design. Another benefit is the ability to collect, analyse and report on total station convergence measurements, reducing the need for multiple software packages or managing and monitoring data in cluttered spreadsheets.

SX12的高分辨率图像捕获与激光扫描功能相结合,可以使测量师从安全距离中快速收集隧道高流量区域的数据。De Vuyst总结说:“总的来说,SX12对项目减少设置和扫描时间的效率和安全性有重大影响。它甚至可以在实时流量情况下使用,因为该软件允许我从点云中过滤掉通过移动流量产生的噪声。”隧道运行后,将收集结构完整性和资产,以提供用于知情的维护决策的数据。

使您的收件箱更有趣。Add some geo.

Keep abreast of news, developments and technological advancement in the geomatics industry.

免费注册